Description

The high pressure Select Doser.

This doser can be adapted to be a proportional doser, an AutoDoser or a single shot doser – but crucially can dose into water line pressure up to 7 bar (100psi).

THE SELECT dosing system has been designed for use in agricultural and other situations where products are required to be dosed into water proportionately to the flow.

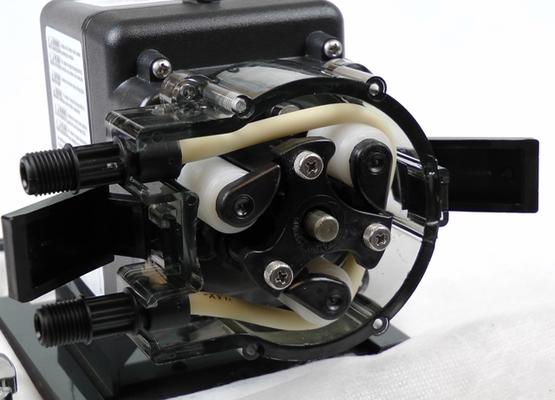

The G5 dosing system combines the tried and tested Select dosing controls with a robust peristaltic pump capable at pumping at high pressure.

USING A PERISTALTIC pump has the advantage that dosed products, regardless of how aggressive they are, only come into contact with the pump tube, not the working parts of the pump. Removing the old tube and fitting the new one effectively cleans and renews the pump.

A SERIES OF simple on-screen menu commands allow the operator to choose between a number of pre-set allowable dosing ratios. The standard range is between 1:20 (5%) and 1:40,000 (0.0025%) in 15 stages covering all of the normal dosing ratios. The range of dosages is achieved by the Select doser using one of six different sized and colour-coded pump tubes. The correct tube to use is indicated on-screen. Additional ratios can be programmed on request up to 1:100,000.

A double pump head (illustrated) can be used to increase output or allow a second product to be dosed.

ACCURACY IS achieved with a unique system of continuous monitoring and adjustment of the pump rotor performance and by a new and unique system of Accumulated Flow Data (the AFD System)

TOTAL WATER use (litres or US Gals) and current water flow (litres (or Gals) per hour) are displayed during dosing. A “meter only” feature means that the Select doser can act as a water meter when dosing is not required.

INSTALLATION IS simple. A flow sensor supplied with the doser is fitted into the line to be dosed. The Select doser and pump are wall mounted and connected to both the signal line from the sensor, and power supplies. Dosed product is pumped into the water line via a valved connector.

THE pump tubes have been tested for stability and durability against most commonly used dosing products including acidifiers and chlorine.

Standard ratios 1: 50; 100; 200; 500; 1,000; 2,500; 3,333; 5,000; 10,000; 20,000; 33,000; 40,000 Max. water flow: 300 – 25,000 l/hr (dependent on ratio) Min. water flow: 20 l/hr Max. pumped output: 21 l/hr Dependant upon configuration Accuracy: Better than 95% Water meter max.: 100,000,000 litres Power: 12V DC, 1.0A and 240V AC Pressure: 6.9 bar (100psi) max. Dose interval: 20 secs. Flow sensor: Threaded connection Filter: Recommended in water line upstream of sensor Delivery lines: LDPE tube

Technical data – G5 Programming

16.03.08 Select 1V G5 Sten

PO Box 103, Saffron Walden, CB11 3GD, United Kingdom e-mail: info@dosingsolutions.com www.dosingsolutions.com T & F: 44(0)1799 551199

Dosing Solutions Ltd

The flow sensor used will vary depending on the range of water flow rates expected.

The G5 programming allows a choice of up to 3 sensors to be chosen from on-screen options.